Zhuhai Zhongya Technology Co., Ltd.

Full-Auto Slitting Machine Manufacturer in China Since 2009

Zhuhai Zhongya Technology Co., Ltd.

Full-Auto Slitting Machine Manufacturer in China Since 2009

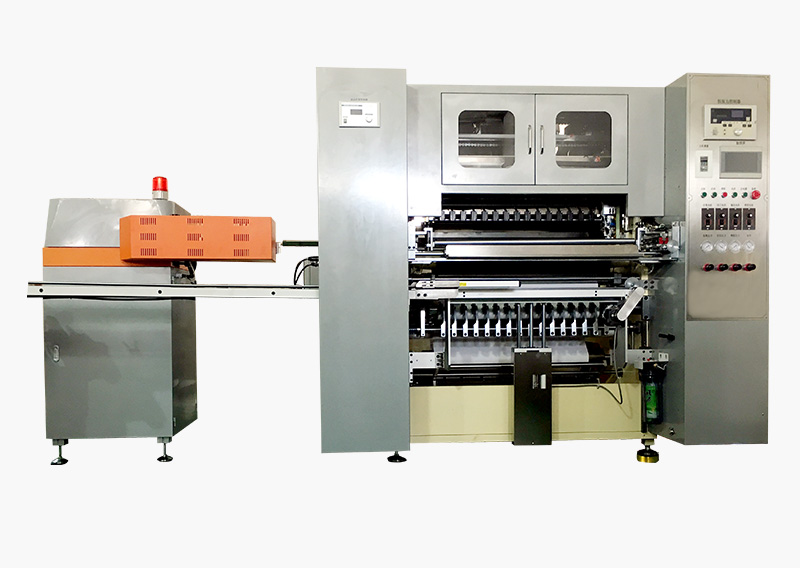

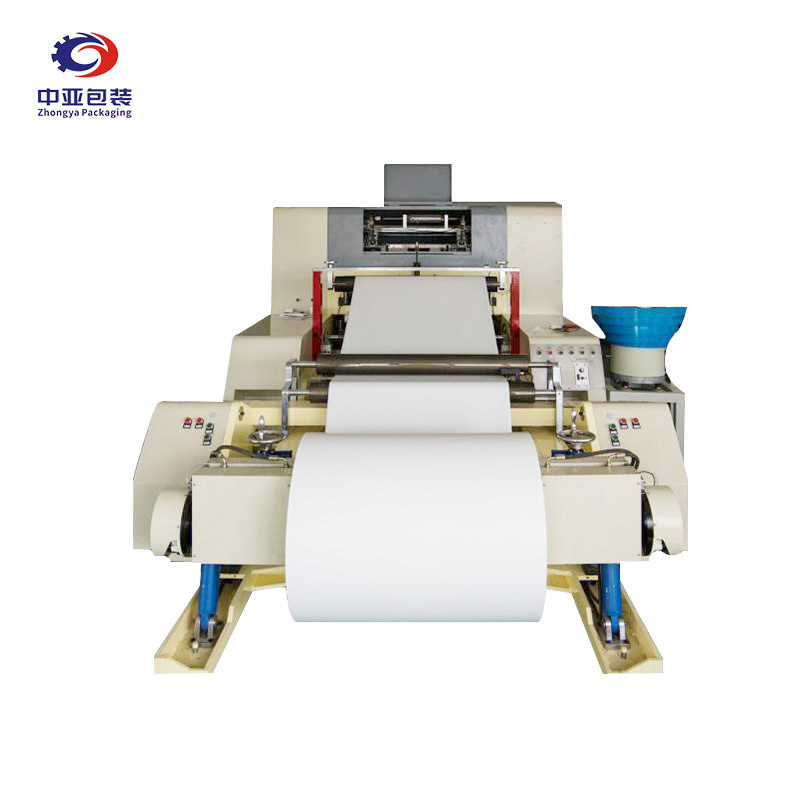

● Imported PLC and touch screen are used to control the system, which is stable and reliable.

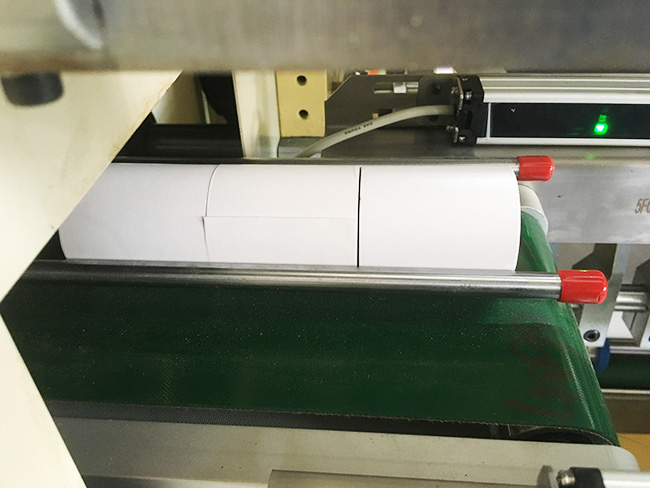

● The reel is controlled by special patented technology, and the press shaft is controlled by variable taper pressure. It can easily adjust the tightness and cope with the vast majority of base paper. It can be sliced smoothly without biting.

● In addition to counting by meters, this machine adds the diameter counting mode, which is the first in the industry to meet the requirements of diameter production conveniently.

● The machine is equipped with coil tail detection and joint detection to meet the requirements of automatic stop of coil tail and joint.

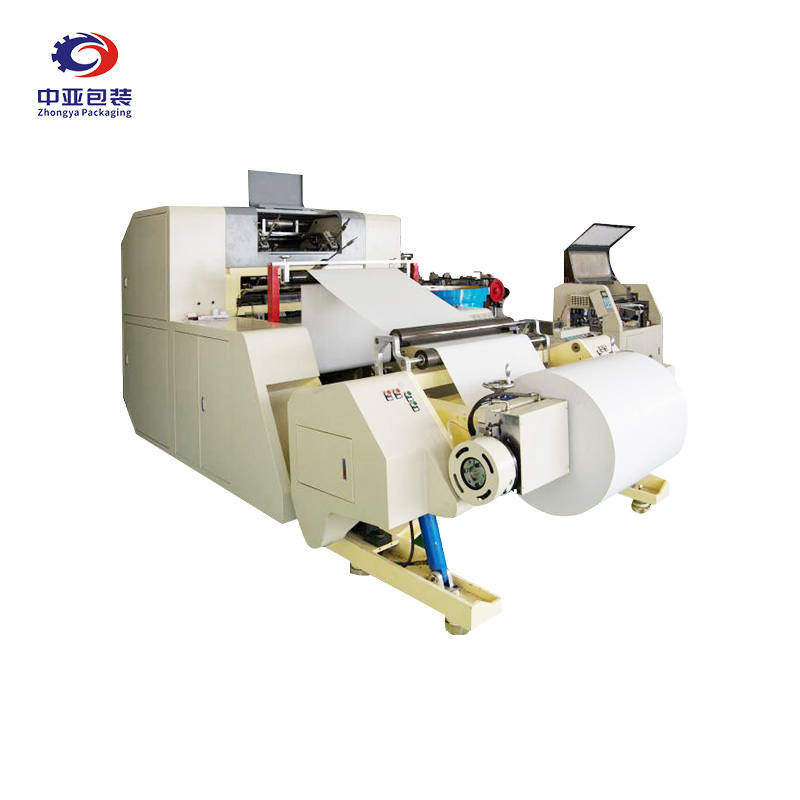

Product type | FQJ-900L-BZO | FQJ-900L-JPO |

Width of paper-roll | 870mm | 400-870mm |

Max. Unreeling diameter | 1000mm | 1000mm |

Max. Reeling diameter | 80mm | 80mm |

Spindle diameter | 13~25mm | 13~25mm |

Slitting width | 30~870mm | 30~870mm |

Operating speed | 200m/min | 200m/min |

● The operating system adds various fault display and alarm to facilitate rapid positioning and handling of various problems and faults.

● The machine is equipped with automatic constant tension, which need not be adjusted in the whole process of slicing.

● Cast iron chassis and base ensures the steady operation of the machine;

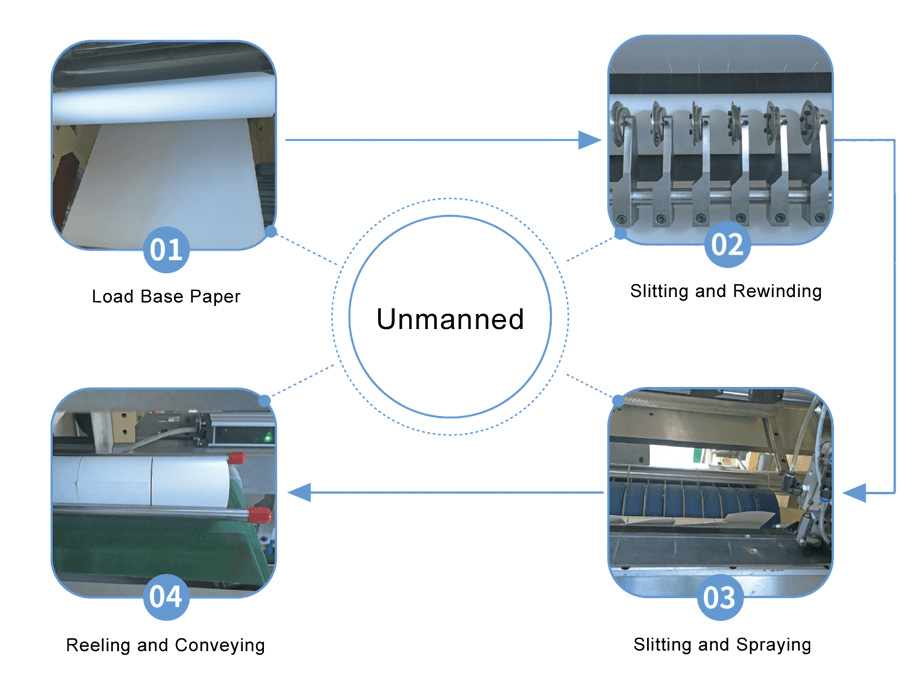

● No manual operation is required.

Copyright 2019 Zhuhai Zhongya Packaging Equipment Co.,Ltd. All Right Reserved.

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist