What causes the instability of label labeling in the multifunctional automatic labeling machine

by:Zhongya Packaging

2022-03-15

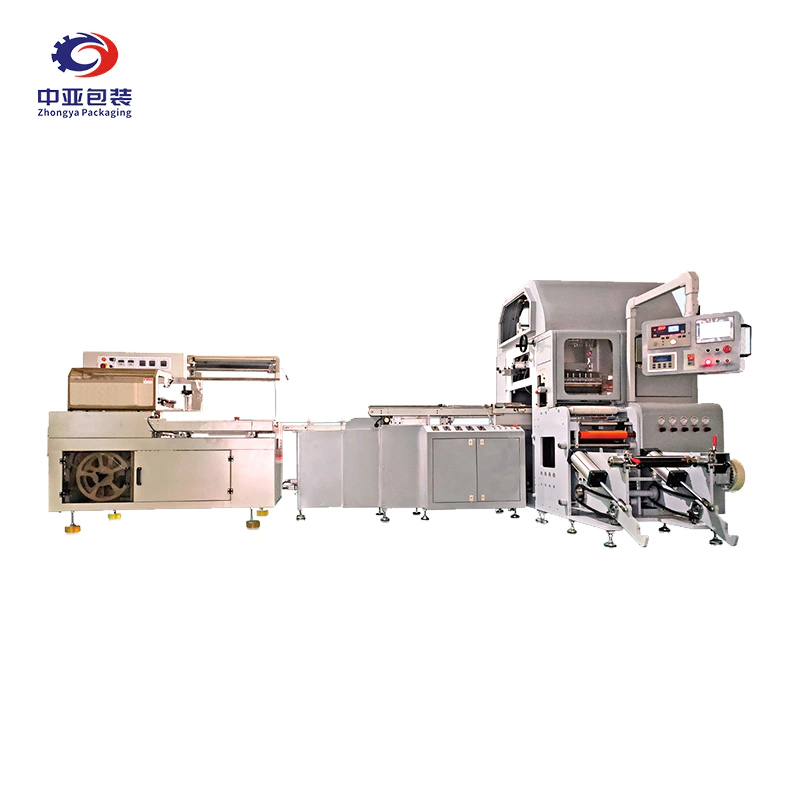

The multi-functional automatic labeling machine adopts the electrical accessories of the first-line big brands. The operation of the whole machine is easy to understand and easy to use, and the labeling speed is fast. Multifunctional automatic labeling machines generally do not have major failures in the initial operation stage, but due to some improper operations, the product labeling will not meet the standards, which will affect the production schedule. In the case, the easy product problem is that the labeling is unstable. Once the labeling machine is not stable enough, it is easy to cause part of the label to be outsourced, and the label is not firmly applied. So when the multifunctional automatic labeling machine is unstable in labeling, how did it happen? Pressure belt configuration factors: If the pressure belt configuration of the multifunctional automatic labeling machine is not compressed or loosened, the position of the label tape will change and loosen, which will affect the label labeling. In this case, we can press the label to solve this problem. Solve such problems. Labeling traction factor: If the traction part of the automatic labeling machine slips or is not pressed tightly, it will cause the bottom paper to stay in the original position and cannot drive the bottom paper to use, then the labeling must be unstable. It will also cause the label to be distorted. To solve this kind of problem, you need to adjust the position and let him pull the low paper normally. Labeling size and position: If the labeling object and position are different or the labeling position is different during the production period, the labeling will be unstable, and if this operation is carried out in the past for a long time, it is also a kind of damage to the equipment itself. Consistent position: The product should be placed in parallel with the labeling direction. Observe whether the labeled product moves during the labeling process. To solve this problem, adjust the support bar to an appropriate height to be parallel. Sometimes when companies need to label multiple products, they need to adjust the labeling position. Because the items to be labeled will be different, it is necessary to re-adjust the labeling angle and position of the labeling machine. The specifics still need to be based on the original parameters provided by the manufacturer. Product production labeling can greatly reduce waste and labeling errors. These five factors all lead to the instability of labeling, which also has a certain relationship with quality. Research should be conducted when selecting a labeling machine manufacturer. An experienced company can make automatic labeling more stable, reduce equipment failure rates, and increase production value. Bogao Sign has more than 10 years of experience in automated back-end packaging. It only sells all kinds of labeling machines. It provides products with integrated services of automatic labeling→visual inspection→code traceability system→intelligent packing and palletizing. For details, you can consult our customers online and provide the most suitable integrated production equipment service for the back-end packaging.

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a