What are the common faults of the self-adhesive labeling machine and its solutions-industry news

by:Zhongya Packaging

2022-05-31

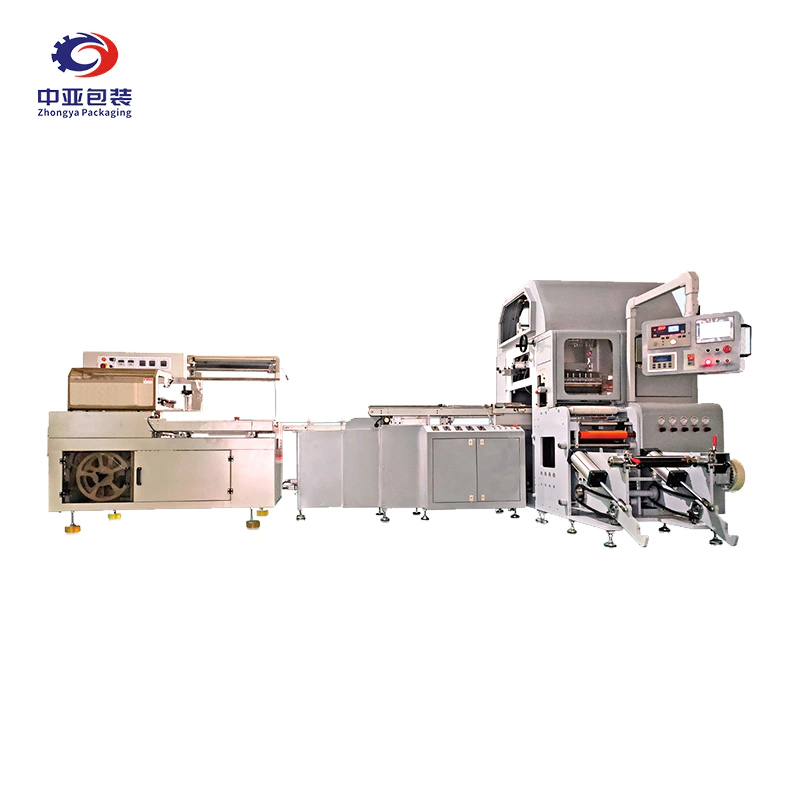

The self-adhesive labeling machine is a kind of facility for self-sealing and binding of cartons. It is a part of the automated packaging industrial equipment. It is usually used in an automated factory with a filling and packaging production line to complete the filling, capping, and pasting of product materials. Marking machine, inkjet printer, self-opening, self-packing, sealing and packing, etc., complete all the work from materials to finished products. Its application range is very wide, and it can be applied to color painting, photo frame, printing, photo album pictures, and cosmetics. , Electronics, medicine, daily chemical industry and other mass production industries. The sealing and packing machine is a kind of packaging industrial equipment that combines the basic functions of self-sealing and self-packing. What are the common failures of self-adhesive labeling machine? And its solution? Although the failure rate of the self-adhesive labeling machine is very low, no matter how you are familiar with it, various minor problems will occur. Then, after reading the following points, compared to the problems encountered by the packaging industry equipment, you will be able to deal with it by yourself. ,save time and energy. What are the common problems in the application of self-adhesive labeling machine? 1. The tape can’t stick to the box. may be due to: a. The main tension spring is very loose; b. The roller shaft has accumulated adhesive and cannot work normally; c. The tape is not up to standard. Solution: Tighten the main tension spring, make these roller shafts smooth, replace the tape 2. The box may be jammed in the middle: a. The adjustment nut of the belt wheel is too tight; b. The height of the box is not scientifically adjusted; c , The self-tensioning spring is too tight. solution: loosen the belt wheel adjustment nut, adjust the height from the beginning, and loosen the main tension spring. 3. The tape breaks during the sealing process. Possible cause: the blade protrudes for too long; Solution: adjust the blade direction. 4, the tape is not on the axis Possible cause: the one-way wheel is broken; Solution: replace the one-way wheel.

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a