Introduction to the composition of the automatic labeling machine-industry news

by:Zhongya Packaging

2022-05-30

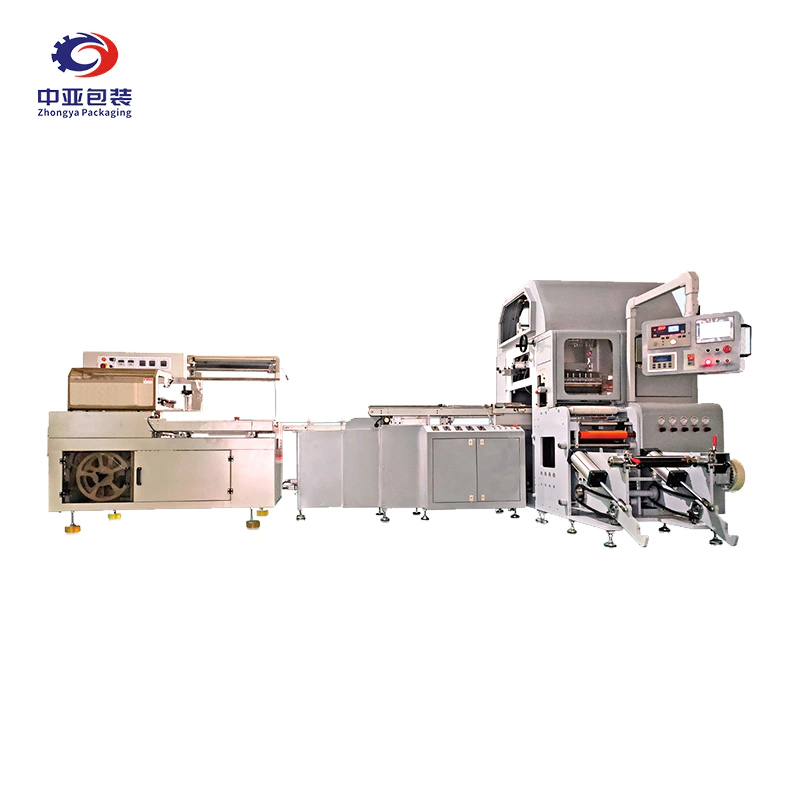

Labeling machine (Labeller) is a device that sticks paper or metal foil labels on specified packaging containers with adhesives. The labeling machine is an indispensable part of modern packaging. At present, the types of labeling machines produced in my country are gradually increasing, and the technical level has also been greatly improved. It has shifted from the backward situation of manual and semi-automatic labeling to the pattern of automatic high-speed labeling machines occupying the vast market. The structure of the automatic labeling machine mainly includes the following components: 1) Peeling board. There is an angle from the end of the board (usually less than 30°), the purpose is to make the label easy to mark out and separate from the backing paper when the backing paper changes direction through the peeling board, so as to achieve contact with the labeling object. 2) Guide roller. It is composed of upper and lower two, which play the role of guiding and positioning the roll material. 3) Buffer wheel. The work is connected with the spring. Can swing back and forth. The purpose is to absorb the tension of the roll material when the device is started, keep the material in contact with the rollers, and prevent the material from breaking. 4) Drive roller. Consists of a set of active friction wheels. Usually one is a rubber roller and the other is a metal roller, with the bottom paper passing in between. The function is to drive the roll material to achieve normal labeling. 5) Rewinding wheel. It is a driving wheel with friction transmission device, which is used to rewind the bottom paper after labeling. The rotation of the take-up wheel does not interfere with the paper-handling of the drive wheel, and the synchronous transmission is adjusted by the friction device. 6) Labeling roller. Apply the label from the bottom paper evenly and smoothly on the article to be affixed. 7) Unwinding wheel. It is a passive wheel, used to place the roll label. It is usually equipped with a friction brake device with adjustable friction force, the purpose is to control the speed and tension of the reel, and maintain a smooth paper feeding. This is the part of the labeling machine. The wheels, plates, and rollers constitute a fully automatic labeling machine, which can help you put the labels on without a single bit of manpower. It is really a good thing that saves time and effort!

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a