If you want a fully automatic labeling machine to improve efficiency, the docking line is the preferred choice-Automatic labeling machine manufacturer-Online printing labeling machine

by:Zhongya Packaging

2022-03-24

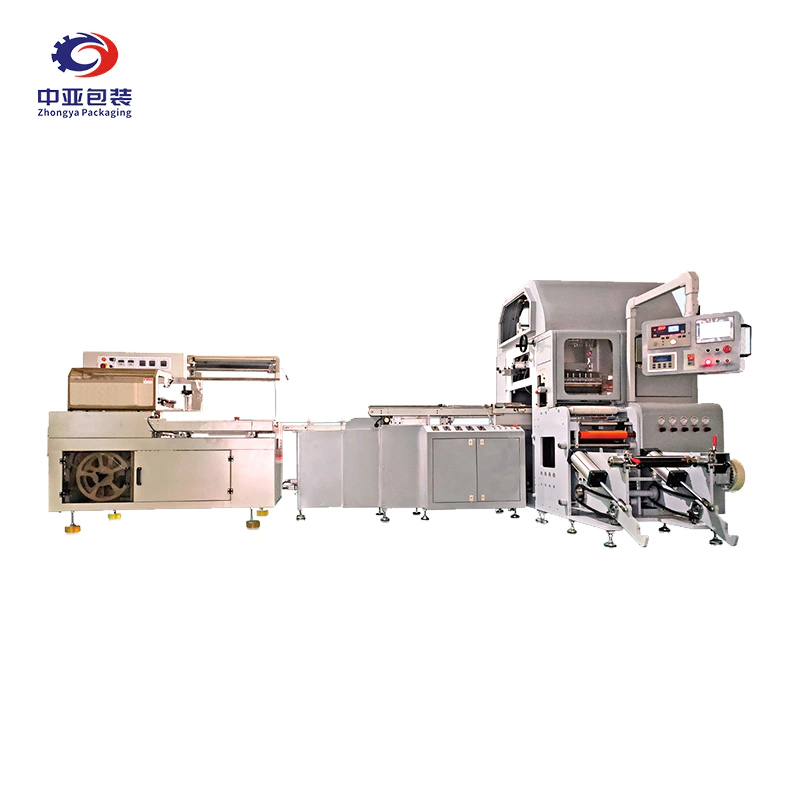

With the development of society and economy, labels, as carriers of commodity information, have increasingly become an indispensable part of modern packaging. Especially for food, medicine and other industries, labels have become an important basis for ensuring safety. Because of the continuous improvement of people’s requirements for packaging, related equipment has been continuously improved accordingly. In order to meet market demand, Bogao Sign Technology Co., Ltd. has developed a new type of labeling machine. Compared with the traditional labeling method, this labeling machine A series of problems such as low manual labeling efficiency and poor labeling quality are avoided, and the waste of paste is effectively reduced. It has the advantages of accurate attaching position, good quality, high stability and high efficiency. To further improve the working efficiency of the labeling machine, we can choose to connect it to the production line, but the following points need to be considered in this process: 1. During the docking process, the guardrail structure of the labeling machine and the assembly line should ensure a smooth connection. , The intermediate processing will not affect the scratch or damage of the item; 2. In terms of speed, it is necessary to match the speed of the labeling machine and the assembly line. On the contrary, the speed of the assembly line must be compatible with the labeling speed of the labeling machine; 3. Labeling For the link structure between the standard machine and the assembly line, use belt or plate chain, and the treatment of the gap should be reasonable; 4. In the process of connecting the assembly line, the overall space should be considered comprehensively to make effective use of the production workshop and not hinder the normal operation of other equipment; 5 , If the labeling machine cannot be connected to the automatic assembly line, you can also consider designing a relatively independent feeding structure and unloading collection structure, so that you can make full use of the efficiency advantages of the labeling machine. As a common packaging equipment, labeling machines can be widely used in food, medicine, daily chemical, electronics and other industries. In these industries, labeling machines are exerting their powerful functions to bring convenience to people, including: 1. Electronics industry: This industry has very professional requirements for labels. In addition to the particularity of label materials, it also has high requirements for labeling machines. The following requirements must be met: it can cooperate with other production links to print and paste large amounts of data in real time, and Ability to communicate with the main system's data, etc. 2. Food industry: With the development of the modern food industry, multi-layer labels provide companies with more extensive publicity and promotion space. At the same time, the design of labeling machines poses new challenges. 3. Daily chemical industry: The requirements in the daily chemical industry often change with each passing day due to the changeable shape of the container. Soft plastic containers and 'unlabeled visual perception' also increase the difficulty of labeling accuracy and bubble elimination control. 4. Pharmaceutical industry: Drug safety is about human health, so there are special requirements for automatic labeling machines, especially in terms of speed. The design of the labeling machine should take into account the integration of the process before and after labeling, and provide labeling front light inspection and Additional functions such as automatic bottle holder after labeling.

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a