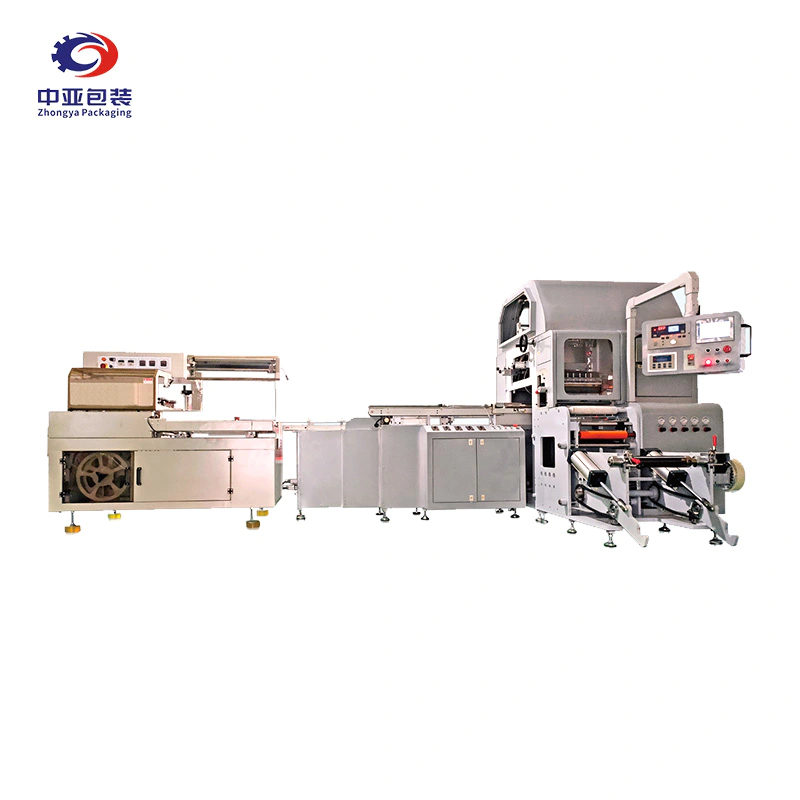

Professional printing automatic slitting production line for sale

How about production process for fully automatic slitting machine?

2020-11-10

From the introduction of raw materials to the sale of finished products, it is necessary to complete a complete set of production processes of fully automatic slitting machine. As for the process, it is the most basic part of the production process. Each process step should be performed by a professional technician to ensure product quality. Providing attentive service is part of the production process. Equipped with a skilled after-sales service team, Zhuhai Zhongya Packaging Equipment Co.,Ltd. can effectively solve problems after you purchase the product.

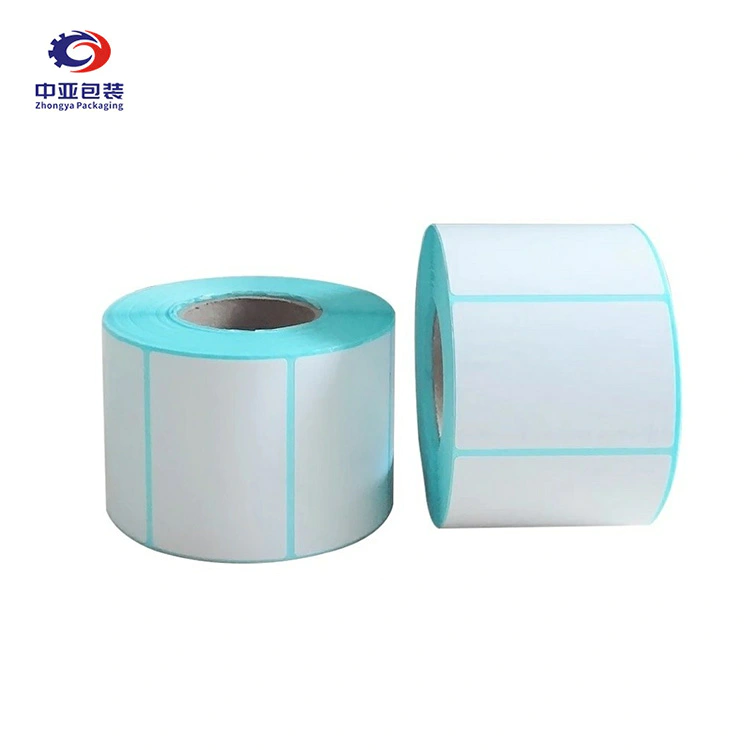

Zhongya Packaging Equipment is one of the reliable manufacturers of fully automatic machine in China. Our in-depth understanding of this industry and product have helped us achieve this distinction. slitting machine produced by Zhongya Packaging Equipmentis very popular in the market. To guarantee the luminous efficiency of Zhongya Packaging Equipmentthermal paper rolls, its semiconductor materials have undergone rigorous screening and only those that meet international standards are selected. This product has been widely used for paper roll products slitting and packaging. This product is not subject to loss of power due to frictional resistance. In the design phase, careful attention has been given to the matter of lubrication of all surfaces which moves in contact with others. Its operating system adds an alarm function to facilitate rapid positioning.

Our company is dedicated to sustainability. We have implemented measures to reduce our footprint on the environment such as producing our own solar energy.

Zhongya Packaging Equipment is one of the reliable manufacturers of fully automatic machine in China. Our in-depth understanding of this industry and product have helped us achieve this distinction. slitting machine produced by Zhongya Packaging Equipmentis very popular in the market. To guarantee the luminous efficiency of Zhongya Packaging Equipmentthermal paper rolls, its semiconductor materials have undergone rigorous screening and only those that meet international standards are selected. This product has been widely used for paper roll products slitting and packaging. This product is not subject to loss of power due to frictional resistance. In the design phase, careful attention has been given to the matter of lubrication of all surfaces which moves in contact with others. Its operating system adds an alarm function to facilitate rapid positioning.

Our company is dedicated to sustainability. We have implemented measures to reduce our footprint on the environment such as producing our own solar energy.

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a