Grasp the labeling process temperature of the labeling machine to make the product perfect-automatic labeling machine manufacturer-online printing labeling machine-shenzhen bogao

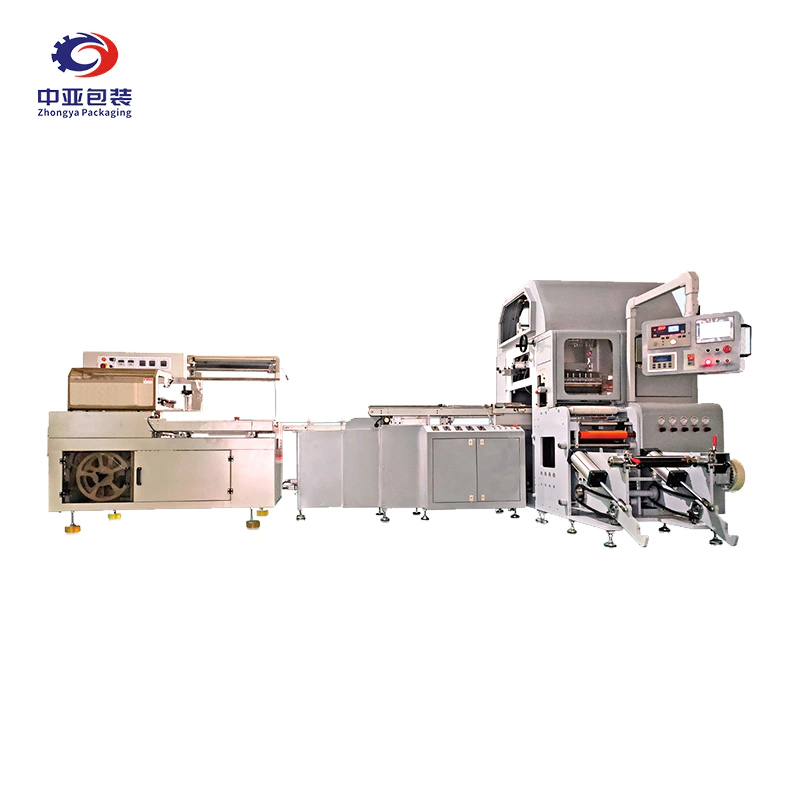

by:Zhongya Packaging

2022-03-21

Along with the needs of the market, various double-sided labeling machines have appeared. After several times of elimination, only the fully automatic double-sided labeling machine is still invincible in the lipstick packaging market. As the name implies, the automatic labeling machine automatically pastes the label on the object to be labeled by the labeling equipment. According to different labels, it is divided into: self-adhesive double-sided labeling machine and paste double-sided labeling machine. The label of the former has glue itself, and the label is peeled off by a self-adhesive labeling machine and then pasted on the object to be stuck, while the label of the paste labeling machine is made of paper without glue, and there is a paste labeling machine. Glue, and then put the label on the object. Compared with the traditional manual labeling method, the fully automatic double-sided labeling machine has the advantages of accurate attaching position, good quality, high stability, and high efficiency. It avoids the inefficiency of manual labeling, skewed attaching, and glue thickness. A series of problems such as unevenness and wrinkles can effectively reduce the waste of paste and reduce the labor cost of labeling. As people enter the stage of aesthetic fatigue for the packaging of various commodities in the shopping mall, the labeling machine has also improved the aesthetics of the product logo to a certain extent, and enhanced the comprehensive competitiveness of the product. Walking into supermarkets and convenience stores, we can see that almost all product packages have labels. These labels can track and manage product sales. If abnormalities occur, they can be recalled accurately and in time. Now they are widely used in daily necessities. Industry. The wide application of labels and the continuous development of label varieties have naturally promoted the development of labeling technology and equipment. In the production process of labeling product packaging, labeling machines play an important role and are an indispensable part of modern packaging. At present, the types of labeling machines in my country are gradually increasing, and the technical level has also been greatly improved. It has shifted from manual and semi-automatic labeling to automatic, high-speed labeling. In the process of the labeling machine we use, the phenomenon of label warping often occurs. Especially in double-sided labeling machine labeling, the problem of label warping is relatively easy to occur. Now that automated production lines are becoming more and more popular, for most products that are first labeled and then filled, capped, sealed, etc., the temperature may rise during the entire process, which may also cause the already pasted The curled corners of the label and the good labeling effect not only give people a sense of beauty, but also give people a sense of guarantee of product quality. It is more attractive to consumers. To achieve a beautiful labeling effect, it is necessary to avoid the phenomenon similar to the labeling in the labeling. There are many solutions to the above-mentioned label warping problem: The key point is to grasp the temperature difference in the labeling process and increase the temperature of the label in advance, so that the process that may need to be heated during the production process is after the temperature rises. The influence of the temperature difference before and after the adhered label is reduced. Of course, increasing the labeling temperature can also increase the active material on the object, thereby increasing the direct adhesion between the label and the product. In most cases, increasing the viscosity of the label is a direct and effective way to solve this problem. Increase the viscosity of the label to make it adhere to the surface of the product more firmly. Furthermore, the strength of the labeling mechanism is increased so that the label can be completely adhered to the surface of the product. When choosing label materials, try to choose softer materials as much as possible. Improving the ductility of the label can effectively improve the problem of label warping. When making labels with a double-sided labeling machine, consider that the shape of the bottom of the label adopts an arc shape, which can effectively avoid the deformation zone.

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a