Automatic round bottle labeling machine high precision semi-automatic flat labeling machine self-adhesive labeling machine price

by:Zhongya Packaging

2022-05-15

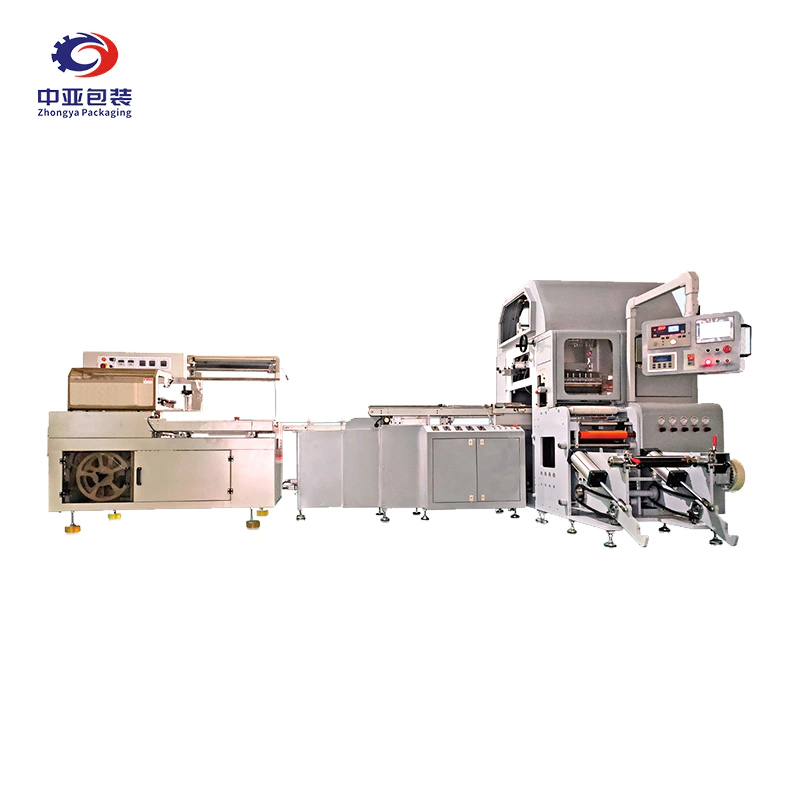

The labeling of round bottle products has always been a headache for manufacturers. Especially those round bottles with smaller diameters are very worrying for manufacturers. The main problems encountered in the labeling of this type of small diameter products are: manual labeling, which is slow; if the machine is used for labeling, if the vertical labeling method is used as usual, the bottle is easy to fall, resulting in unstable transportation and labeling. A situation where the effect is not good. But do you know that there is a special round bottle automatic labeling for this kind of product labeling? You have never heard of the horizontal automatic round bottle labeling machine. This type of equipment is a labeling equipment specifically for small diameter round bottle products. It can well solve the problem of unsatisfactory labeling effect caused by product or bottle standing unstable. At present, small-diameter round bottle products are mainly concentrated in the medicine, cosmetics, food, chemical and other industries. The small round bottles in these industries are mostly made of glass. Therefore, when purchasing a dedicated horizontal automatic round bottle sticker When marking the machine, whether the feeding is smooth and the receiving is reasonable, this is a technical point of main concern. However, since the editor has talked about this issue, I will certainly not let everyone entangled in the choice of equipment. The editor recommends a Bogao horizontal automatic round bottle labeling machine for you to understand. Product use: Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc. Applicable products: small products requiring labels or films to be attached to the circumferential surface or small cone surface. Application industry: widely used in medicine, cosmetics, electronics, hardware, plastics and other industries. Application examples: solid plastic bottle labeling, oral liquid bottle labeling, pen holder labeling, lipstick labeling, etc. Working principle: The separating wheel separates the products and puts them on the conveyor belt. The sensor detects the passing of the products and sends back a signal to the labeling control system. The control system controls the corresponding motor to send out the label at the appropriate position and attach it to the product to be labelled. When the product flows through the labeling device, the labeling belt drives the product to rotate, the label is rolled, and the attachment of a label is completed. Operation method: Place the product (put it in the feeding box) —> separate the product and spread it out between the conveyor chain roller —> product delivery —> product inspection —> labeling —> labeling —> collect the labeled products. Self-adhesive label production requirements: 1. The distance between the label and the label is 2-4mm; 2. The distance between the label and the edge of the bottom paper is 2mm; (Avoid cutting the bottom paper); 4. The inner diameter of the core is 76mm, and the outer diameter is less than 260mm, arranged in a single row. The above label production needs to be combined with your product. For specific requirements, please communicate with our engineers and the results shall prevail! Product features: High labeling efficiency, side-horizontal roller conveyor mechanism, inclined conveyor chain, automatic bottle guide, stable conveying and labeling. The labeling speed is as high as 300 bottles per minute, which saves a lot of manpower and material resources. The product qualification rate is high. The application of flexible bottle separation technology and flexible labeling technology makes the separation and labeling action extremely smooth, and the bottle breaking rate is less than one hundred thousandths; The labeling accuracy is high, and the label tape deflection correction technology is adopted, and the label head and tail are highly overlapped; the rolling type labeling, the labeling is flat, without wrinkles, and no bubbles, which improves the packaging quality; high stability, Mitsubishi PLC+Weinen The advanced electronic control system composed of touch screen + Panasonic needle-shaped electric eye + German Sick labeling electric eye, supports 7×24 hours of high-speed operation of the equipment; intelligent control, automatic photoelectric tracking, with no objects and no labeling, automatic calibration and automatic label detection Function to prevent leakage and label waste; solid and hygienic, mainly made of stainless steel and high-grade aluminum alloy, in line with GMP production specifications, strong structure, beautiful and generous; with fault alarm function, production counting function, power saving function, production number setting prompt Function, parameter setting protection function, convenient for production management; Optional functions: ①Hot coding/printing function; ②Automatic receiving function (combined with product consideration) ③Automatic feeding function (customized according to customer requirements)

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a