Analysis of the structure, principle and application of automatic labeling machine-automatic labeling machine manufacturer-online printing labeling machine-shenzhen bogao

by:Zhongya Packaging

2022-03-05

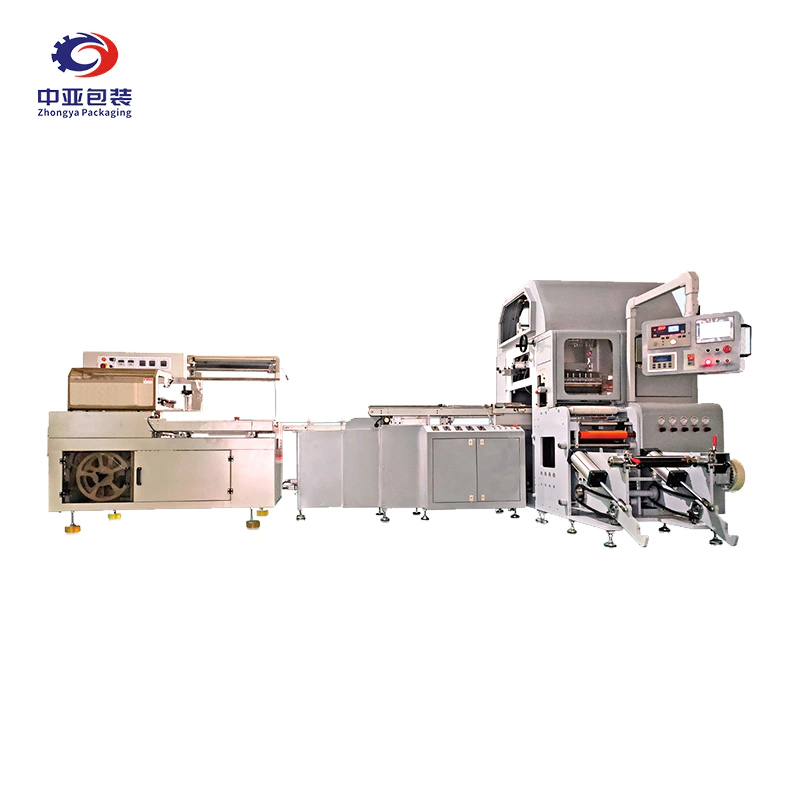

The automatic labeling machine is a device that pastes rolls of self-adhesive paper labels or other suitable materials on PCBs, products or specified packaging. It is widely used in electronics, furniture, beverages, daily chemicals, food, medicine, petrochemicals, etc. Labeling of packaging containers and boxes of the industry’s products. With the development of all walks of life, more and more companies are turning to automation, intelligent equipment, reducing labor costs, improving efficiency and other needs. The types of labeling machines are also increasing, and they have gradually changed from manual and semi-automatic labeling. Automated high-speed labeling machine occupies the pattern of the market. 1. The components of the labeling machine In addition to the bar code printing equipment, the labeling machine is responsible for providing labels and recycling backing paper to complete the labeling action. It is the core component of the labeling machine. It is mainly composed of 1. Unwinding reel 4. Drive roller 2. Unwinding buffer 5. Pressure roller 3. Peeling plate 6. Bottom paper recovery buffer 2. Working principle of the labeling machine Feed to the labeling machine at a constant speed. The mechanical fixing device separates the boxes by a fixed distance and pushes the boxes along the conveyor belt. The mechanical system of the labeling machine includes a driving wheel, a labeling wheel, and a reel. The driving wheel drags the label tape movement intermittently, the label tape is pulled out from the reel, and the labeling wheel will press the label tape on the box after passing through the labeling wheel. An open-loop displacement control is used on the reel to maintain the tension of the label tape. Because the labels are closely connected to each other on the label tape, the label tape must constantly start and stop. The label is attached to the box when the labeling wheel moves at the same speed as the box. When the conveyor belt reaches a certain position, the label belt drive wheel will accelerate to a speed that matches the conveyor belt, and after the label is attached, it will decelerate to a stop. Since the label belt may slide, there is a registration mark on it to ensure that each label is placed correctly. The registration mark is read by a sensor. During the deceleration phase of the label tape, the drive wheel will readjust its position to correct any position errors on the label tape. 3. Classification of labeling machines Due to the different types of labeling objects and the different material shapes of the labels themselves, the labeling requirements are also different. Therefore, in order to meet the labeling requirements under different conditions, there are different types and varieties of labeling machines. 1. According to the product type: linear labeling machine and rotary labeling machine. 2. According to the degree of automation: automatic, automatic, semi-automatic and manual labeling machines. 3. According to the realization of different labeling functions: flat labeling machine, side labeling machine and circumferential labeling machine; 4. According to the container Operation direction: vertical labeling machine and horizontal labeling machine 5. According to labeling process characteristics: pressure labeling machine, rolling labeling machine, rolling labeling machine, brush stroke labeling machine 6 , According to different adhesive coating methods: self-adhesive labeling machine, paste labeling machine (adhesive labeling machine, glue labeling machine) and hot melt adhesive labeling machine; 7. Types of labels: Sheet label labeling machine, roll label labeling machine, hot-adhesive label labeling machine, pressure sensitive labeling machine and shrink tube label labeling machine; 8. According to the length of the label: single-sided labeling Machine, double-sided labeling machine, three-side labeling machine and multi-side labeling machine. Fourth, the scope of application of the labeling machine The following is the classification of the realization of different labeling functions to talk about the scope of application of the labeling machine 1. Flat type labeling The machine is to realize labeling and filming on the upper plane and upper arc surface of the workpiece, such as boxes, books, plastic cases, etc. There are two methods of rolling and sucking. The selection is mainly based on efficiency, accuracy and bubble requirements. 2. The round bottle labeling machine realizes labeling or filming on the circumferential surface of cylindrical and conical products, such as glass bottles, plastic bottles, etc., and can realize circumferential, semicircular, circumferential double-sided, circumferential positioning labeling and other functions. There are mainly two ways of vertical labeling and horizontal labeling. 3. The side labeling machine realizes labeling or filming on the side plane and side arc surface of the workpiece, such as cosmetic flat bottles, square boxes, etc., can be equipped with round bottle labeling equipment, and realize round bottle labeling at the same time.

Custom message

+ 86-0756 386 7226

+ 86-0756 386 7226  a

a