Zhuhai Zhongya Technology Co., Ltd.

Full-Auto Slitting Machine Manufacturer in China Since 2009

Zhuhai Zhongya Technology Co., Ltd.

Full-Auto Slitting Machine Manufacturer in China Since 2009

•The wallboard of 2000*1300*35 mm is formed by a large computer gong once to ensure the accuracy of the whole machine

•The connection of the two wallboards adopts the most solid and stable way, which is pioneered in the industry;

•All mechanical fittings are treated by six-sided grinding, forging and hardening, and never rust

•Each shaft is subjected to heat treatment, fine grinding and dynamic balancing

•The reel is controlled by special patented technology, and the press shaft is controlled by variable taper pressure.

It can easily adjust the tightness and cope with the vast majority of base paper. It can be sliced smoothly without biting;

•All bearings are NSK imported bearings, suitable for long-term operation at high speed.

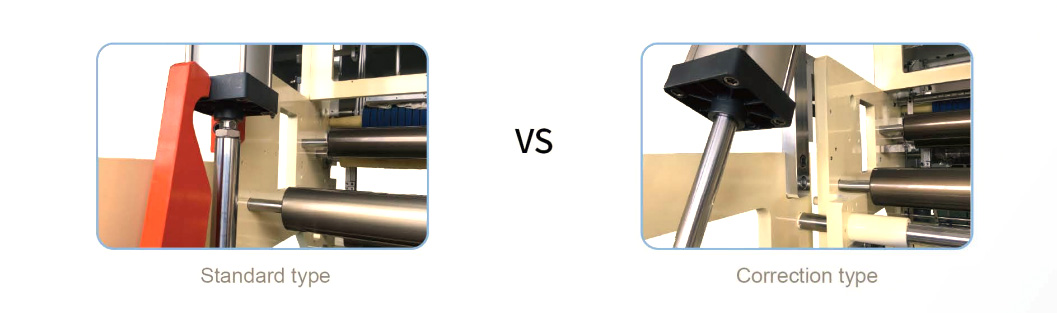

The width of standard type's paper roll is 750-870mm, while the width of correction type's paper roll is 400-870m.

External size (L*W*H) | 2500*2000*1850mm | Maximum base paper diameter | <01000mm |

Area covered | 3000*3000mm | Inner diameter of base Paper cylinder | 3 inch |

Total weight | 3T | Number of layers of wrapped paper | Single layer |

Input power supply | 380V/50HZ(60HZ) | Unwinding tension | Auto-tension control |

Power | 7KW | Winding diameter | 03O-085mm |

Gas source | Compressed air greater than >10KG | Core diameter | 015-026mm |

Matching air compressor | >10P | Counting method | Metric number and diameter |

Control mode | PLC+touch screen | Maximum slitting speed | 200m/min |

Slitting material | 50g-80g web | Max slitting base paper width | <09OOmm |

Copyright 2019 Zhuhai Zhongya Packaging Equipment Co.,Ltd. All Right Reserved.

We are here to help you! If you close the chatbox, you will automatically receive a responsefrom us via email. Please be sure to leave yourcontact details so that we can better assist